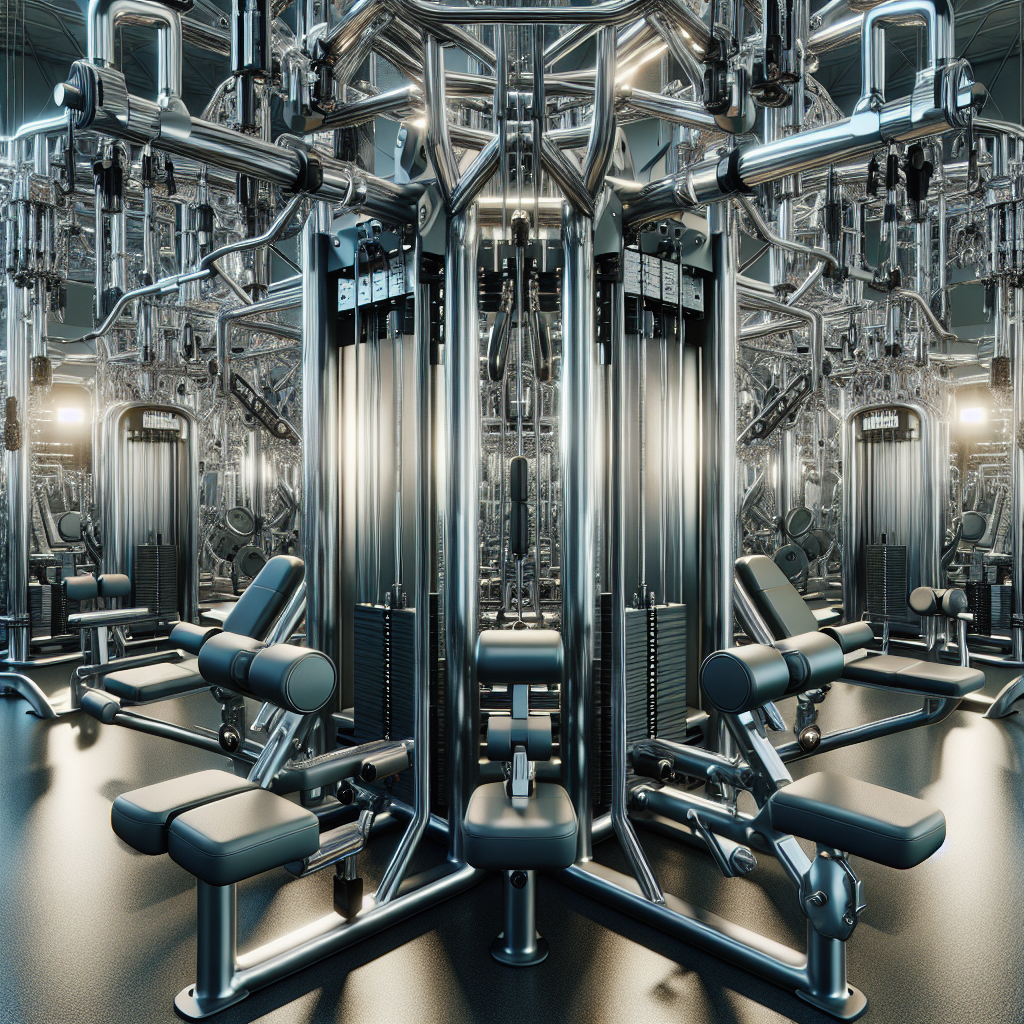

Multistation and weight machines are the backbone of any commercial gym, providing a comprehensive workout experience by incorporating multiple exercise stations into a single unit. These machines are engineered to offer versatility, allowing users to execute a range of workouts targeting different muscle groups without needing to switch equipment. From leg presses to lat pulldowns, multistation machines are designed to maximize efficiency and space in fitness facilities.

However, like any piece of gym equipment, multistation and weight machines require regular maintenance and occasional repairs to ensure they remain in optimal working condition. *Proper upkeep not only prolongs the lifespan of the machines* but also ensures the safety and satisfaction of gym-goers. In this article, we’ll delve into essential tips for maintaining and repairing these vital pieces of fitness equipment.

For *professional maintenance and repair services*, contact us or visit our website.

Common Issues in Multistation Equipment

Despite their robust design, multistation machines can encounter several common issues that can hinder their performance. Recognizing these problems early on can save time and money while preventing potential injuries.

- Cable Wear and Tear: Over time, the cables in multistation equipment can fray or snap due to constant tension and use. It’s crucial to inspect cables regularly for signs of wear and replace them promptly.

- Pulley Malfunctions: Pulleys may become misaligned or worn out, causing uneven tension and reducing the effectiveness of workouts. Ensure pulleys are lubricated and functioning smoothly.

- Loose Bolts and Screws: Regular use can cause bolts and screws to loosen, which can compromise the stability of the machine. Periodically check and tighten all hardware to maintain structural integrity.

- Seat and Padding Wear: The seats and padding on these machines can deteriorate over time, leading to discomfort and potential hygiene issues. Replace any damaged or worn padding to maintain user comfort and cleanliness.

- Weight Stack Issues: Misaligned or stuck weight stacks can disrupt the smooth operation of the machine. Regularly check the alignment and functionality of weight stacks to ensure they move freely.

Addressing these common issues promptly can help maintain the efficiency and safety of your multistation equipment, ensuring a better experience for users.

Essential Tools for Machine Repair

Having the right tools on hand is crucial for effectively repairing and maintaining multistation and weight machines. Ensuring you are well-equipped can make the repair process smoother and more efficient.

- Adjustable Wrenches: These are essential for tightening and loosening bolts and screws of various sizes, making them versatile tools for any repair job.

- Hex Keys: Also known as Allen wrenches, hex keys are vital for assembling and disassembling parts of gym equipment, as many machines use hex bolts.

- Screwdrivers: A set of flathead and Phillips screwdrivers is necessary for handling different types of screws found in gym machines.

- Lubricants: Keeping pulleys, cables, and other moving parts well-lubricated ensures smooth operation and reduces wear and tear.

- Replacement Cables and Pulleys: Having spare cables and pulleys on hand can significantly reduce downtime when these parts need replacing.

- Multimeter: This tool is useful for diagnosing electrical issues in machines that have electronic components.

- Cleaning Supplies: Regular cleaning with appropriate supplies helps maintain the equipment’s hygiene and appearance while preventing dirt and debris from causing mechanical issues.

Possessing these essential tools not only aids in immediate repairs but also helps in conducting regular maintenance, ensuring your fitness equipment remains in optimal condition.

Step-by-Step Repair Guide

Repairing multistation and weight machines can seem daunting, but following a systematic approach can simplify the process. Here is a step-by-step guide to help you navigate common repairs:

- Identify the Issue: Begin by diagnosing the problem. Observe the machine and listen for unusual noises. Check for visible signs of wear, such as frayed cables or loose bolts.

- Gather Necessary Tools: Refer to the list of essential tools to ensure you have everything you need before starting the repair. This will save time and prevent interruptions during the process.

- Turn Off and Unplug the Machine: For safety, always make sure the machine is turned off and unplugged from any power source before beginning any repair work.

- Disassemble the Affected Area: Use the appropriate tools to carefully disassemble the parts of the machine that need attention. Keep track of all screws, bolts, and small components to ensure easy reassembly.

- Inspect and Replace Damaged Parts: Thoroughly inspect each component for damage. Replace any worn-out or broken parts with high-quality replacements to ensure the machine operates smoothly post-repair.

- Lubricate Moving Parts: Apply lubricants to pulleys, cables, and other moving parts to reduce friction and prevent future wear and tear.

- Reassemble the Machine: Carefully reassemble the parts, ensuring everything is tightly secured. Double-check your work to make sure all components are correctly installed.

- Test the Machine: Plug the machine back in and turn it on. Test its functionality to ensure the repair was successful. Pay attention to any unusual sounds or issues that might indicate further problems.

- Perform Regular Maintenance: To prevent future issues, establish a routine maintenance schedule. Regularly clean, inspect, and lubricate the machine to keep it in optimal condition.

Following these steps can help you effectively repair and maintain your multistation and weight machines, ensuring they remain safe and functional for users.

Preventive Maintenance Tips

Preventive maintenance is crucial for extending the life and performance of your multistation and weight machines. By incorporating these preventive maintenance tips into your routine, you can avoid costly repairs and ensure the safety of users:

- Regular Inspections: Schedule regular inspections of your equipment. Look for signs of wear and tear, such as frayed cables, loose bolts, and worn-out pads. Early detection of issues can prevent more extensive damage.

- Clean Equipment Frequently: Dust and sweat can accumulate on machines, leading to corrosion and malfunction. Wipe down equipment daily with a damp cloth and mild detergent. Pay special attention to high-touch areas like handles and seats.

- Lubricate Moving Parts: Apply appropriate lubricants to moving parts, such as pulleys and cables, at least once a month. This reduces friction and wear, ensuring smooth operation.

- Tighten Loose Components: Regularly check and tighten any loose screws, bolts, and nuts. Loose components can lead to instability and increase the risk of accidents.

- Check Cables and Belts: Inspect cables and belts for any signs of fraying or damage. Replace them immediately if any wear is detected to prevent sudden failures during use.

- Test Safety Features: Ensure that all safety features, such as emergency stop buttons and safety locks, are functioning correctly. Regular testing can help prevent accidents and injuries.

- Monitor Usage: Keep track of the usage patterns of your equipment. Machines in high-traffic areas may require more frequent maintenance compared to those used less often.

- Train Staff: Educate your staff on proper usage and basic maintenance tasks. Well-informed staff can help identify issues early and maintain equipment effectively.

By implementing these preventive maintenance tips, you can significantly enhance the longevity and reliability of your multistation and weight machines, ensuring a safer and more productive workout environment for all users.

Why Professional Repair Services Matter

When it comes to maintaining and repairing multistation and weight machines, opting for professional repair services can make a significant difference. Here are several reasons why professional repair services matter:

- Expertise and Knowledge: Professional technicians possess the necessary expertise and knowledge to diagnose and fix problems accurately. They are trained to handle various types of gym equipment and can address issues that might be overlooked by untrained eyes.

- Quality Assurance: Professional repair services ensure that repairs are done correctly and meet industry standards. This guarantees the safety and reliability of your equipment, reducing the risk of malfunctions and accidents.

- Time Efficiency: Attempting to repair equipment yourself can be time-consuming and may lead to further complications. Professionals can quickly identify and resolve issues, minimizing downtime and getting your equipment back in operation faster.

- Cost-Effectiveness: While DIY repairs might seem cheaper initially, improper fixes can lead to more significant problems and higher costs in the long run. Professional services provide cost-effective solutions that prolong the life of your equipment.

- Access to Genuine Parts: Professional repair services have access to genuine replacement parts, ensuring that your equipment functions as intended. Using authentic parts can prevent further damage and maintain the machine’s integrity.

- Preventive Maintenance: Many professional services offer preventive maintenance plans that help identify potential issues before they become critical. This proactive approach can save you money and keep your equipment in top condition.

Investing in professional repair services not only enhances the performance and longevity of your gym equipment but also ensures the safety and satisfaction of your users. For reliable, expert repair services, contact us at: info@MaxPowerRepairs.com.